4D Printing and Beyond

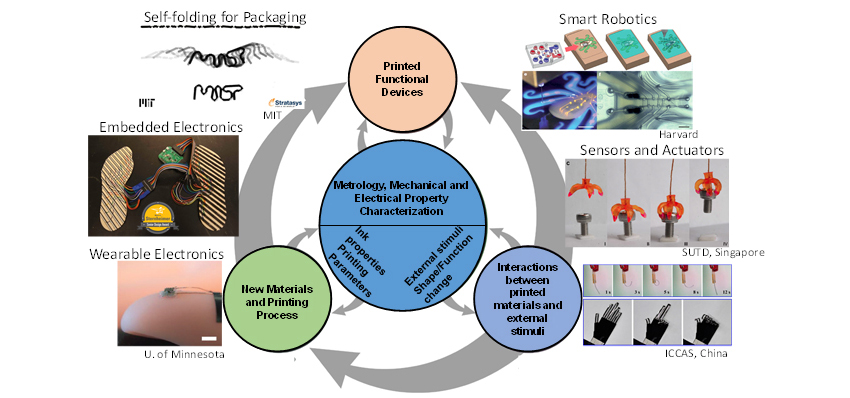

Traditional 3D printing are limited to prototypes or simulators with fixed shapes and limited functions. 4D printing, as an emerging new area in additive manufacturing, uses the same 3D printing technology with one big difference: the printed object can change its shape upon environment in a controlled and pre-programmed way, e.g. water, heat, light, electric field, etc. The shape transformation (or morphing) is realized through material selection, pre-programed shape designs and printing process. This VIP team will initiate multiple projects covering object design (AutoCAD or SOLIDWORKS), simulation (ANSYS) of morphing process, material selection, development of printing process of the functional materials, and interface to external circuits if applicable. Students will explore various 4D printing of functional materials, investigate the interactions of the printing material and the external stimuli to pre-program the shape-changing mechanism, establish signal processing and communication for functional devices targeting specific applications. The students engaged in this work will not only gain knowledge about science and additive manufacturing, but also obtain training in research methods and critical thinking.

Projects will include:

- Design and development of printing processes for self-assembled devices upon exposure to water.

- Design and development of printing processes for a “robotic hand” using responsive materials.

- Design and build an extrusion-based 3D/4D printer, and develop gel printing processes.

Interested? Contact Prof. Hong Zhao (hzhao2@vcu.edu)